Creativity looking for accuracy

Group companies

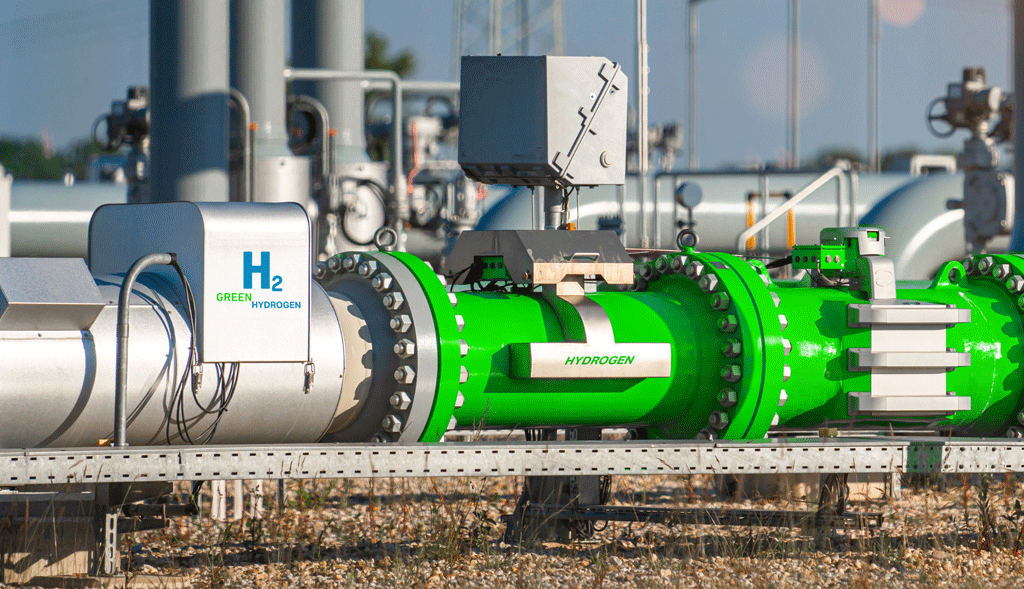

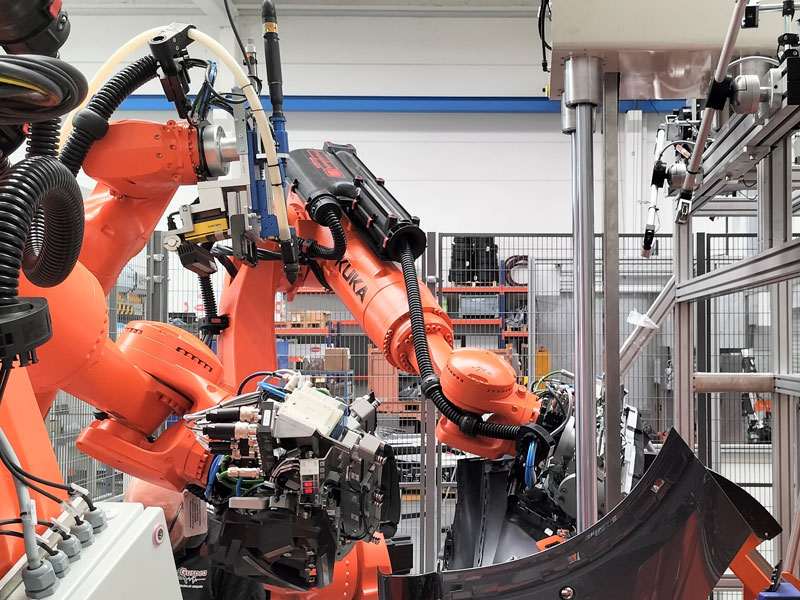

The search of excellence has led GURPEA GROUP to diversify its business lines in order to offer a specialized integral service and more sustainable solutions in emerging markets.

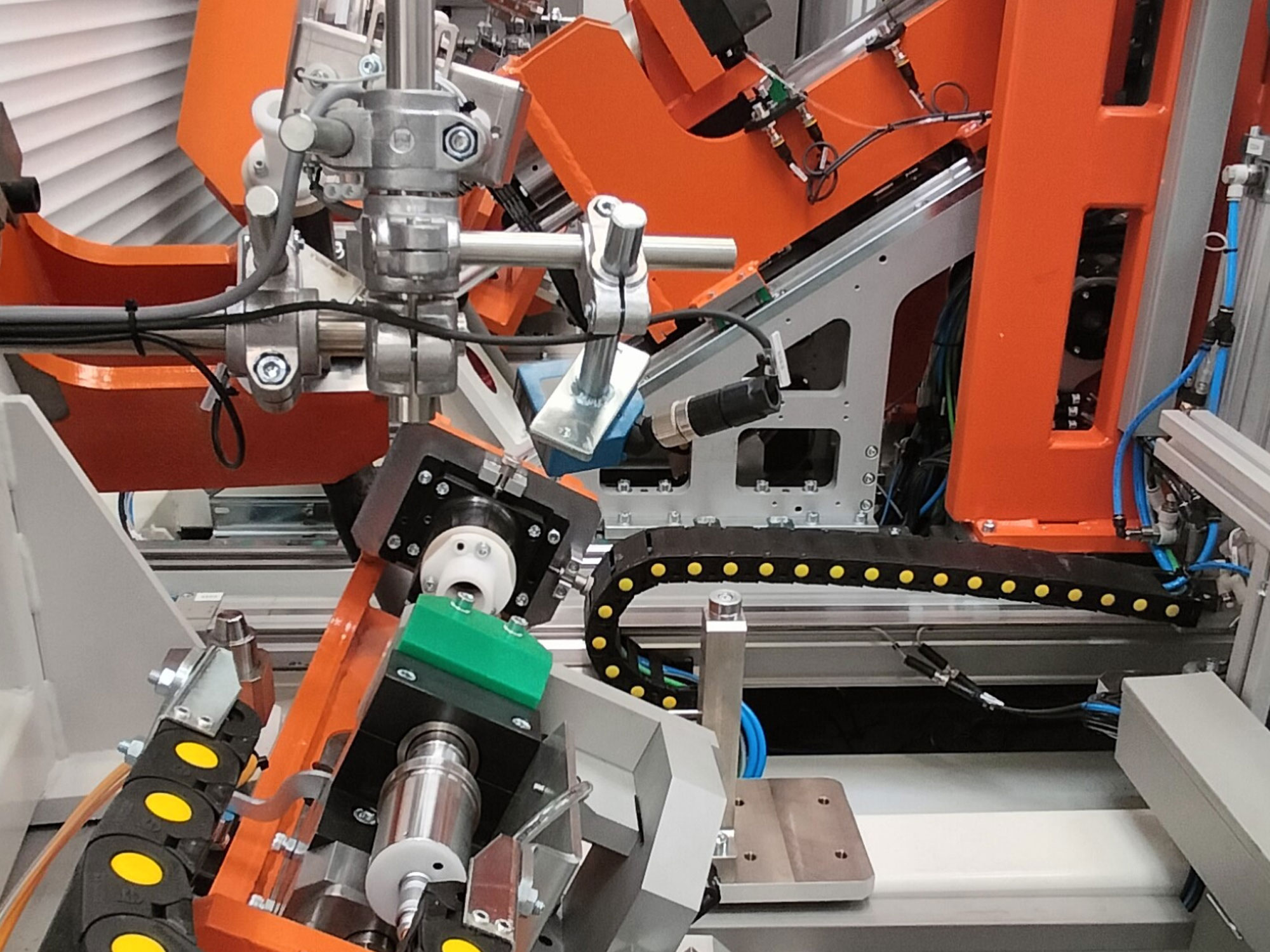

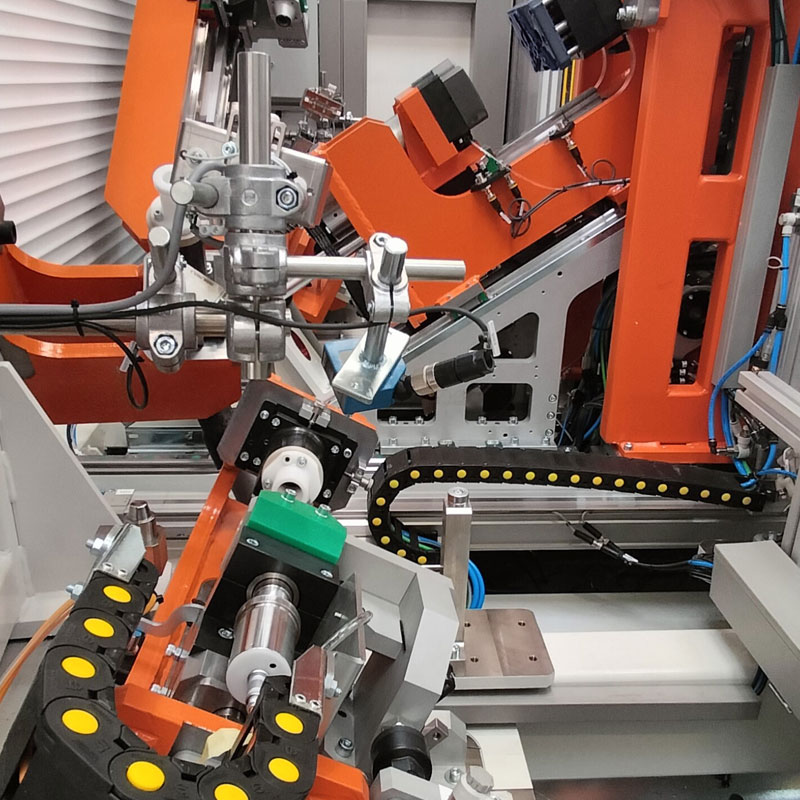

A differential and highly competitive option

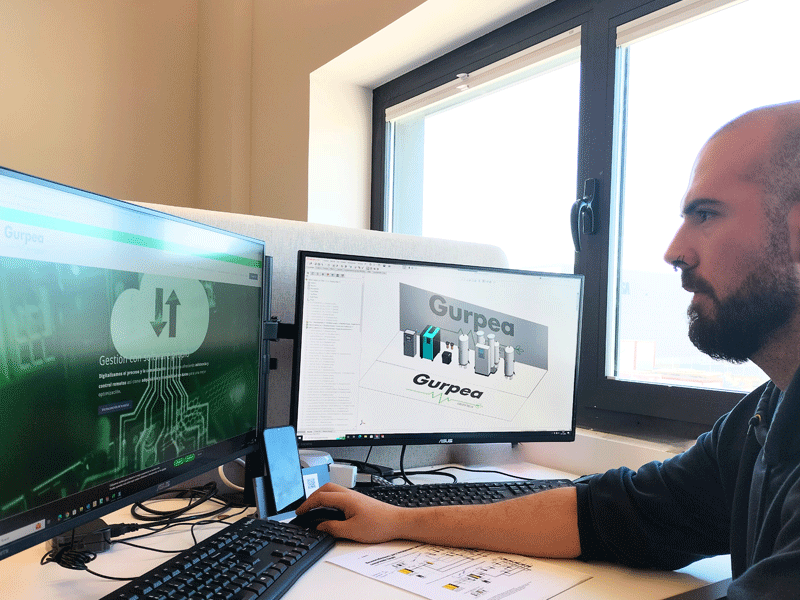

Internationalization and business diversification, towards sustainable engineering, as growth strategies, position the group as a differential and highly competitive option in the market. Supported by a professional and committed senior team made up of people with extensive experience in various sectors.

Gurpea Group

data

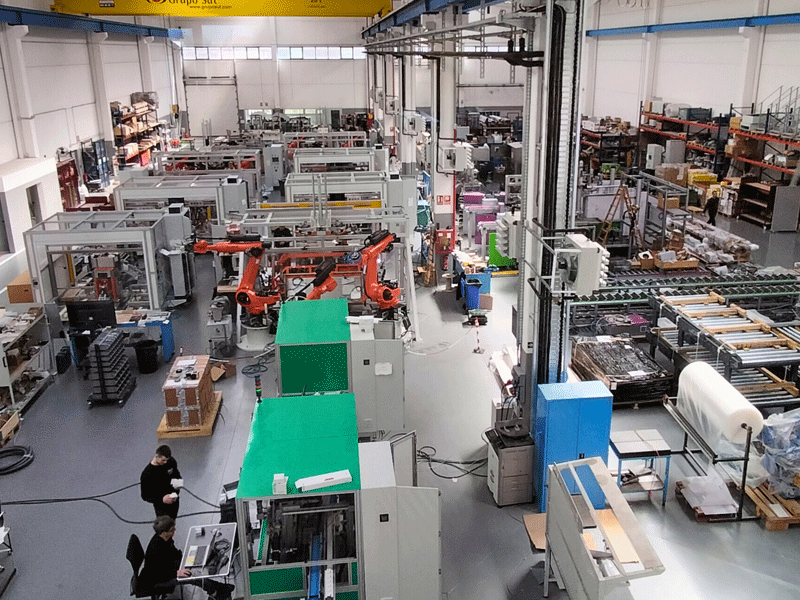

The UNION is the STRENGTH of the GURPEA GROUP, which offers a strong structural and economic support to the business divisions that are part of it.

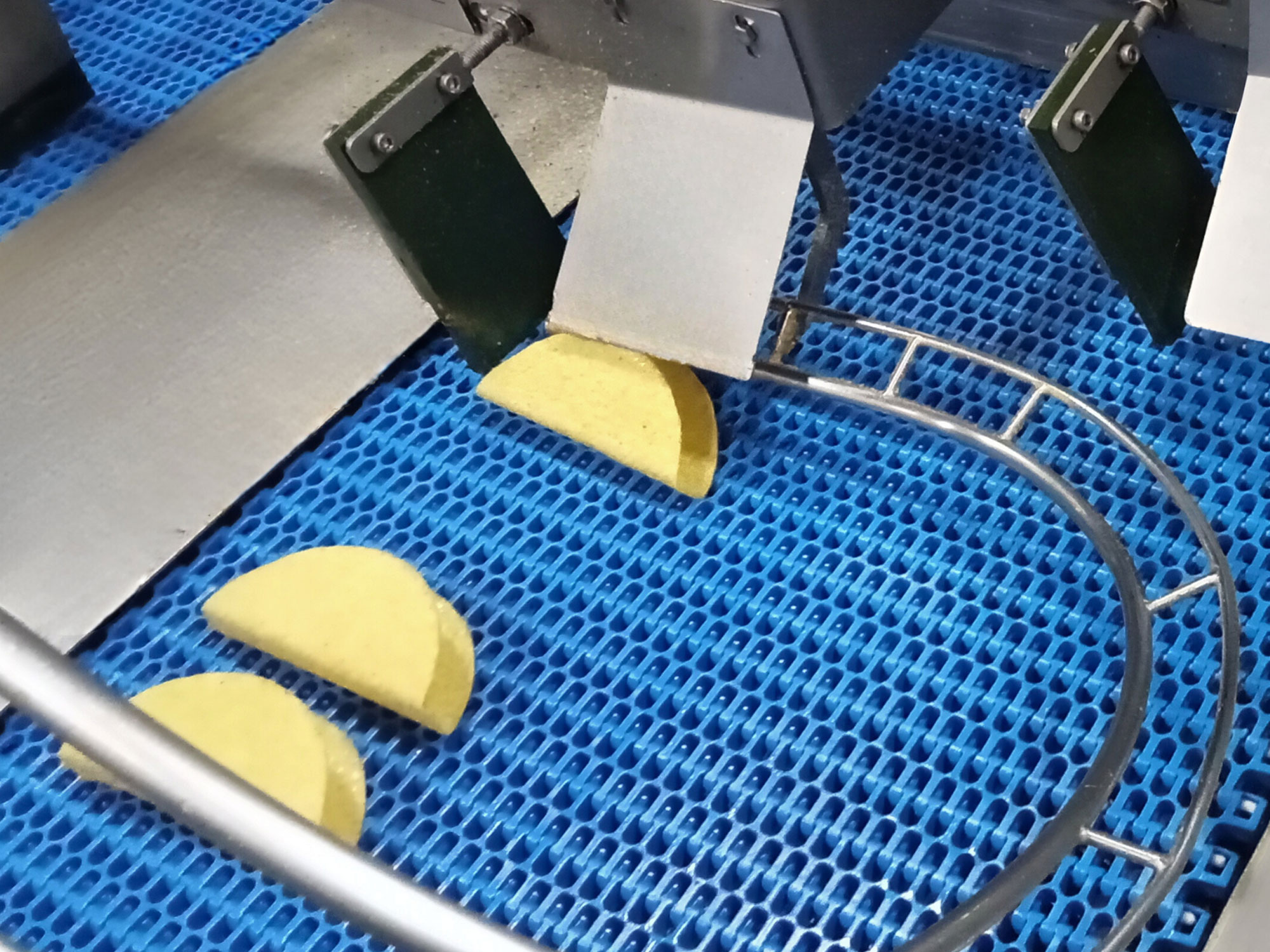

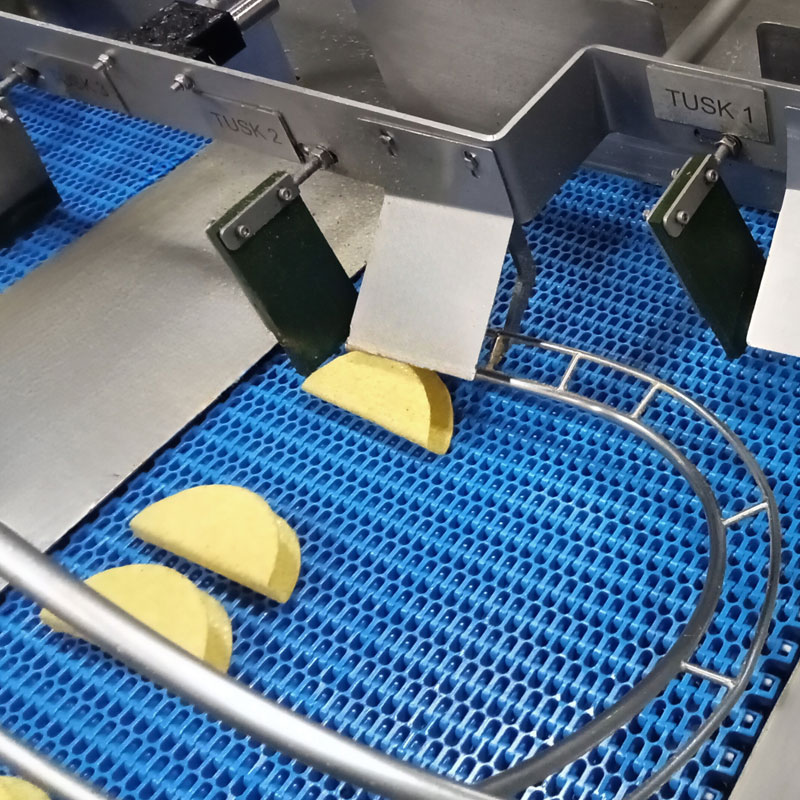

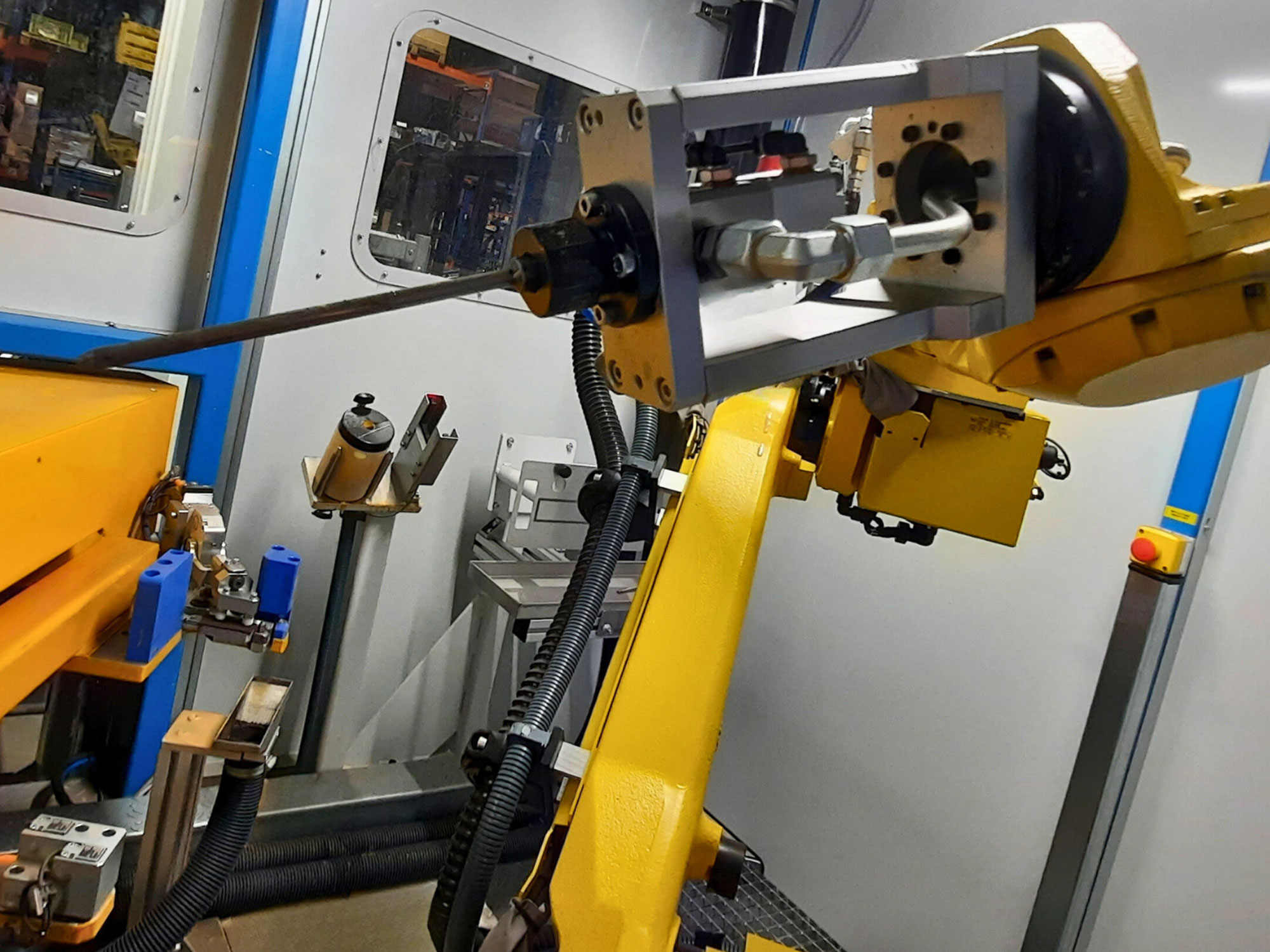

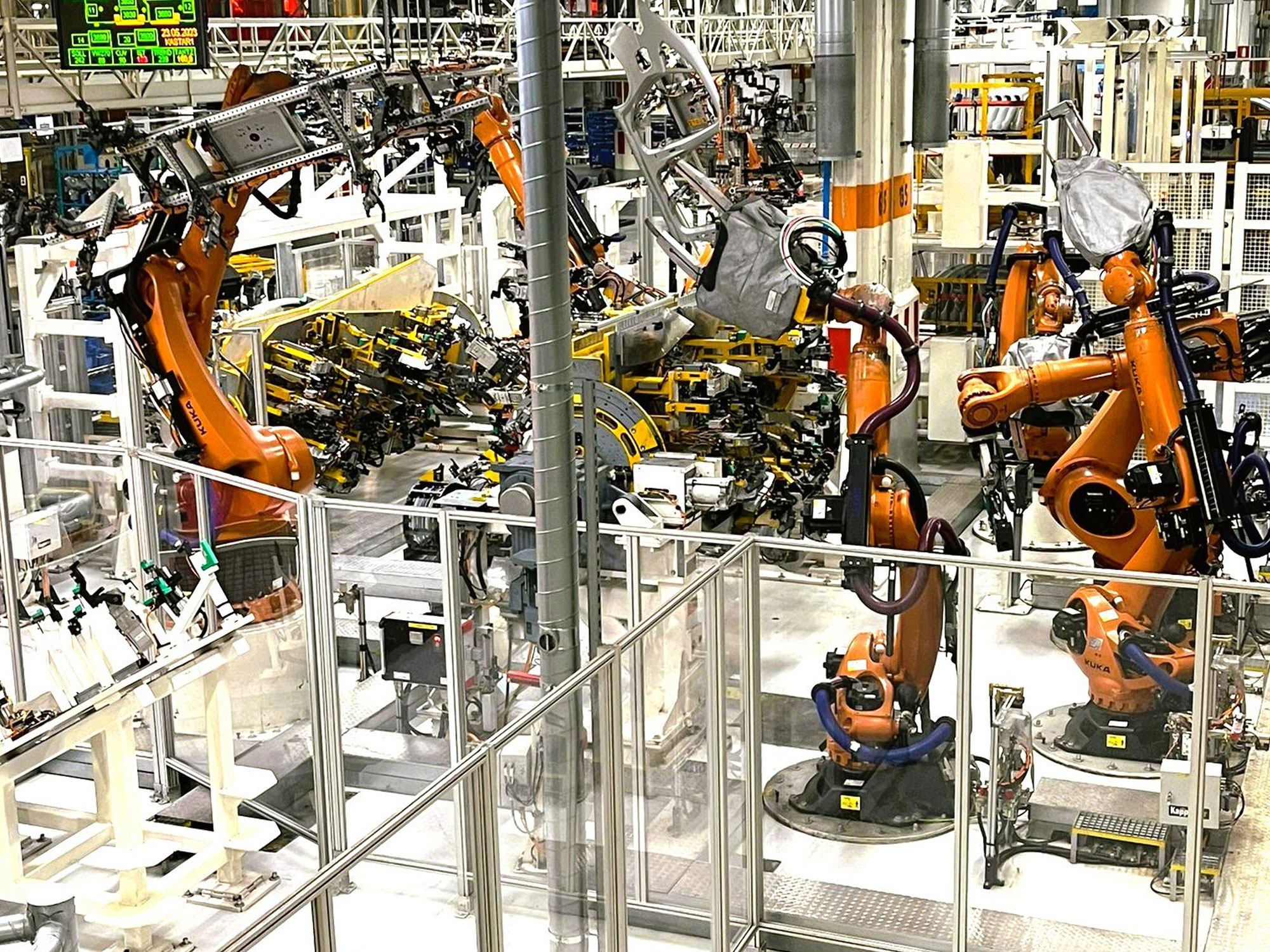

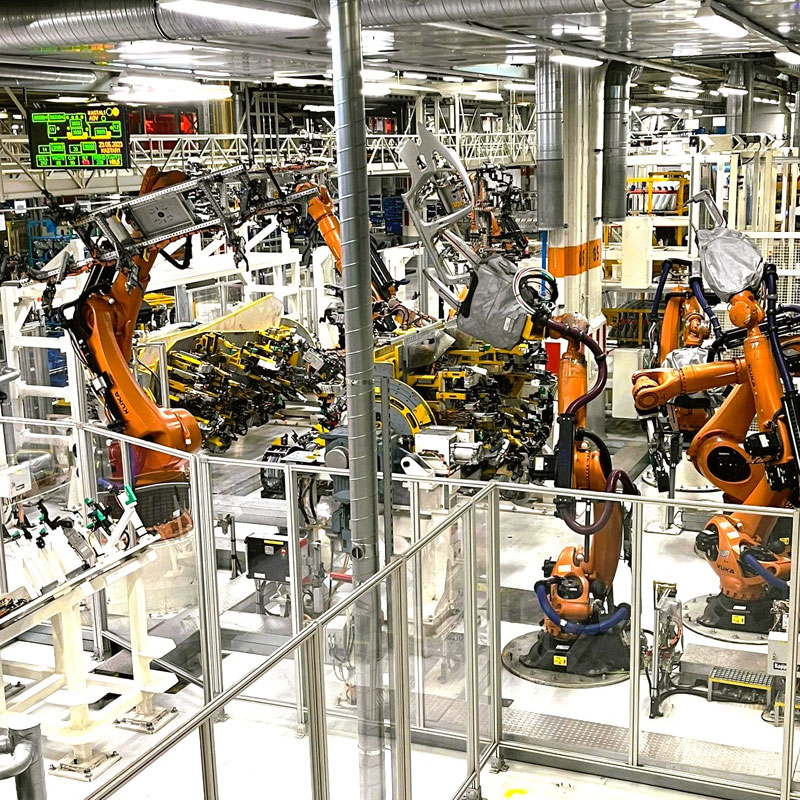

Sectors

The multi-sector know-how place GURPEA GROUP as a universal option in the market, capable of adapting to any sector, product and technology.

Activity sectors distribution (%)

Contact our team

Write us! a GURPEA GROUP expert will contact you.